High Definition Heating Furnace Industry Camera System

Series No. STV7100

The system adopts the advanced imaging technologies and high-temperature protection technologies, has the characteristics of HD image, advanced protection technology, automatic protection, etc. The products can be applied in metallurgy, petrochemical, cement, glass, electricity and other industries, can continuously monitor the work conditions and manufacturing process of various heating furnaces, and is the updated product of domestic & abroad similar high-temperature industrial monitors.

1. Real-time monitoring the movement condition of slab inside the furnace.

2. Real-time monitoring the wearing situation of lining inside the furnace.

3. Real-time monitoring the flame condition inside the furnace.

4. Enter and withdraw device to ensure the safety of camera protector

5. On-line maintenance possible.

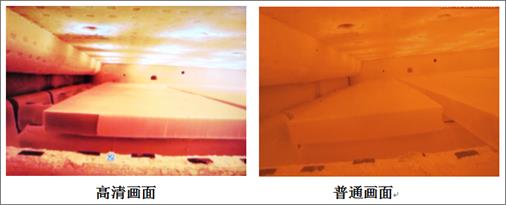

1. High Definition Camera

The system is using a 800×600 high definition camera, a special coated high temperature lens to ensure the sharpness of image.

2. Unique Noise Reduce Technology

The camera is customized made using our company’s unique noise reduce design. Which can provides a better Signal-Noise Ratio (SNR).

3. Advanced Self-Protection System

This system is adopted our Enter-and-Withdraw device, when the system detects cooling medium supply pressure drops, or inside temperature of camera protector increase. The protector withdraws from the furnace.

4. Safety Protection

The system adopts a gravity drive furnace door. When the camera protector withdraws from the furnace, the door will close by gravity, and fully seal to ensure on-site worker’s safety.

HD Monitor Image V.S. Common Monitor Image

|

Cooling Medium |

Cooling Air |

Inlet Pressure |

0.4~0.7 MPa |

|

Pipe Diameter |

DN25 |

||

|

Flow |

0.8M³/min |

||

|

Cooling Water |

Pressure |

0.3~0.4MPa |

|

|

Flow |

1M³/h |

||

|

Power Supply |

Power Supply |

AC220V 50Hz |

|

|

Power Consumption |

1000W |

||