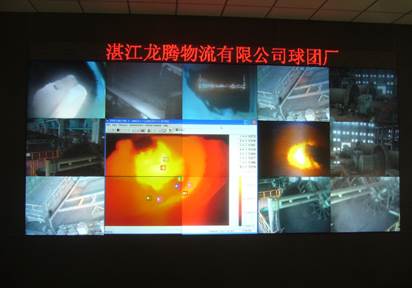

Rotary Kiln Thermal Infrared Monitoring System

Series No. STV6300

STV6300 Rotary Kiln Thermal Infrared Monitoring System is a monitoring device designed for Rotary Kiln working environment. The system provides clear image and accurate temperature measurement for optimize rotary kiln process.

1. Real time monitoring the working condition inside the rotary kiln.

2. Real time monitoring the wearing of lining.

3. Real time temperature measurement with allowance within ±3°C.

4. 640×480 pixels high definition.

5. More than 300,000 temperature measurement points.

6. Automatically save all data and video into system

7. Automatically enter and withdraw device

8. On-line maintenance supported.

1. Sharp Lens and High Resolution Camera

The system combines a 640×480 high-resolution camera and a special coated heat resistance lens to ensure the sharpness of image.

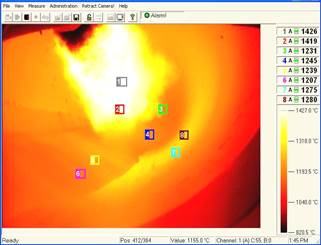

2. Intelligence Software

The intelligence software measures the temperature inside the kiln, the system allows the operator choose up to 48 from 300,000 temperature points. The system will automatic measure the temperature of these points, and generate a temperature profile.

All video and data will be writing into system automatically.

3. Advanced Protection

The system is adopted with automatic enter and withdraw system, when the supply of cooling medium is irregular, or the temperature inside the protector is higher than preset value, the system will automatically withdraw. This also makes on-line maintenance available.

|

Cooling |

Cooling Air |

Inlet Pressure |

0.4~0.7 MPa |

||

|

Air supply pipe diameter |

DN40 |

||||

|

Flow |

0.8M³/min |

||||

|

Cooling Water |

Pressure |

0.3~0.4MPa |

|||

|

Flow |

1M³/h |

||||

|

Power |

Power Supply |

220V AC 50Hz |

|||

|

Power Consumption |

1000W |

||||