Blast Furnace Top Infrared Monitoring System

- with Auto-Swipping Device

Series No. STV4700A

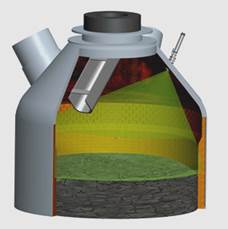

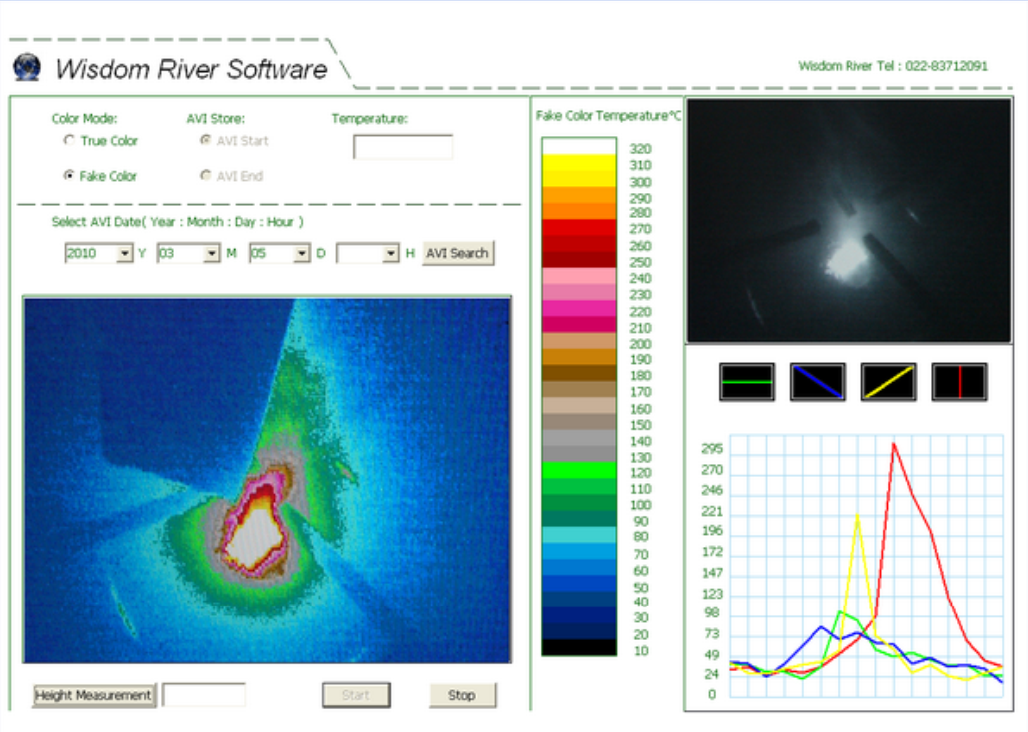

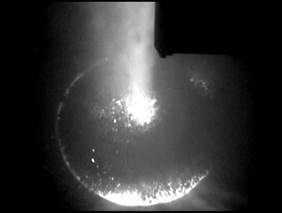

STV4700 Blast Furnace Top Infrared Monitoring System is a kind special monitoring system that installed on the top of Blast Furnace to monitor the airflow, burden, and swing chute of Blast Furnace. The system is using 780-1100nm wavelength near-infrared camera to provide a clear sharp image.

1. Real-time monitoring of Burden surface and airflow distribution.

2. Real-time monitor the motion of swing-chute inside Blast Furnace.

3. Real-time monitor the temperature distribution of the burden surface, and generate temperature profile.

4. Automatic lens cleaning device adopted.

5. Video recording function

6. On-line maintenance supported.

1. Ultra Low Temperature Camera

The system is using infrared camera with extremely sensitive wave length – 780nm – 1100nm. This offer the system can capture image when the object’s temperature is higher than 90°C.

2. Deposit dust clean system

The system is using our company’s design. The protector adopted a lens-cleaning device inside, which can automatically clean the deposit dust in a certain time period

3. Ultra Wide Field of View Lens

The system is using a ultra wide lens which offers 110° field of view (FOV).

4. Safety

The system applies a unique gate valve and ball valve. When the protector withdraws the gate valve and ball valve automatically close, to prevent the spill of coal gas. There is a check-valve structure, when the coal gas supply broken or sudden pressure drop. The structure can prevent the spilling of coal gas.